Fix My Duck

I worked closely with Mark, owner of Stephenson Amps on the overhaul of the Fix My Duck pedal, optimizing it for efficient manufacturing. This started with component selection for the pedal's circuitry. We built prototypes and Mark tuned them meticulously until the perfect sound was achieved.

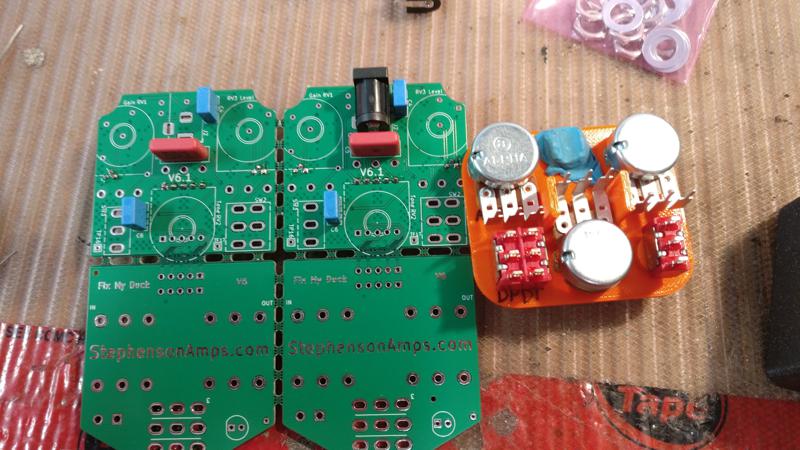

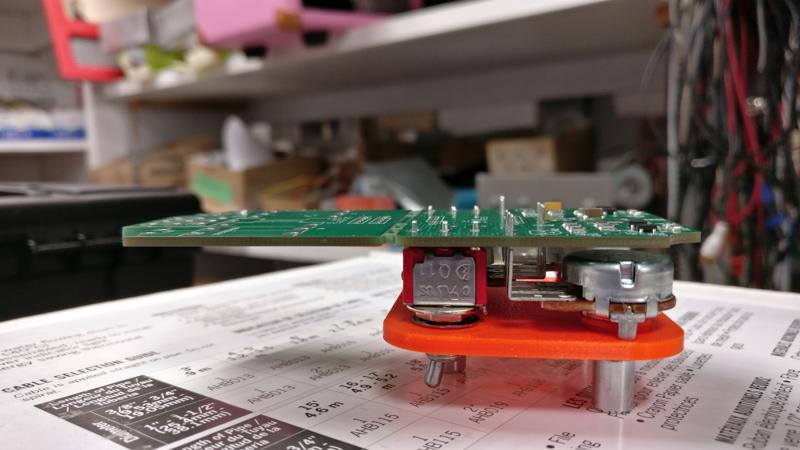

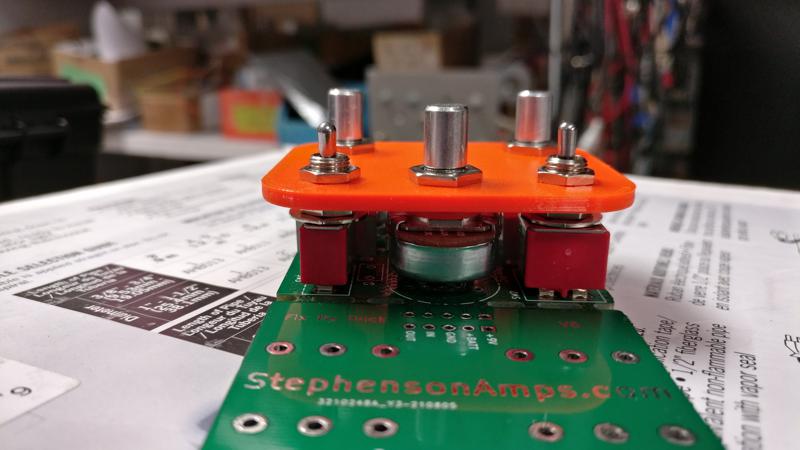

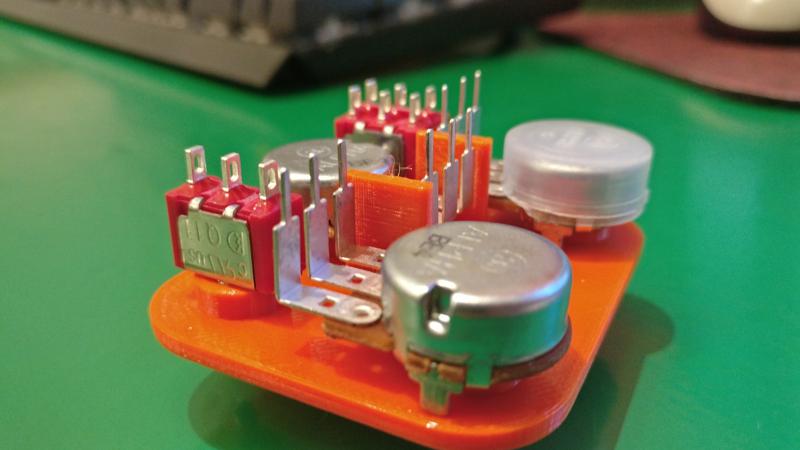

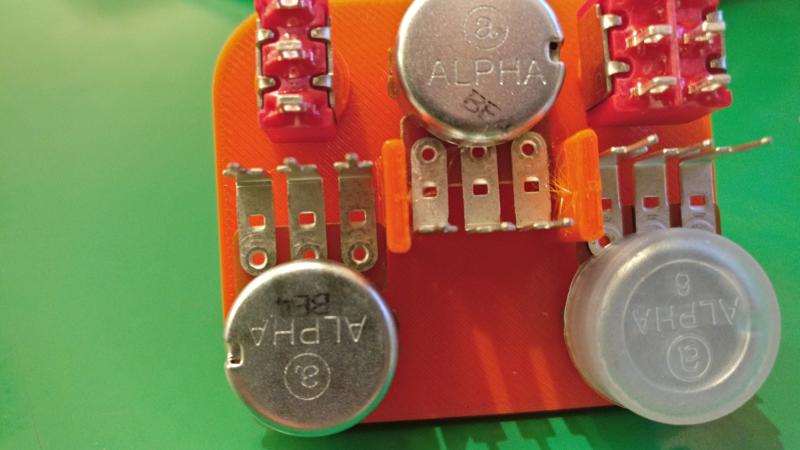

I decided to use a stack of PCBs to accommodate the spacial requirements of the through-hole components. Using 3D modeling and printing helped to quickly iterate the fitment to ensure everything would come together smoothly. This allowed for us to work out any problems before having the PCBs manufactured. The two PCBs could be assembled and tested together before being snapped apart and stacked.

I designed and fabricated an assembly jig that ensured precise alignment of components. This not only increased soldering efficiency, but also improved the overall consistency and quality of each unit.

In parallel, I used CAD and 3D printing to determine the placement of the holes in the off-the-shelf box to be professionally manufactured with CNC machining.

Additionally, I digitized the hand-painted pedal graphics for UV printing with Adobe Illustrator. This improved the consistency of the pedal's aesthetics and reduced defects, aligning with Stephenson Amps' commitment to form, function and quality.

If you would like your own contact Mark or order one on Reverb